The need for a contaminant-free space to manufacture medicine has led scientists to try many creative new approaches to improve the process. At Argonne National Lab, creating a device that floats and rotates chemical compounds in thin air was just the answer they were looking for. It meant two important changes: the amount of each chemical necessary could be implemented very precisely and the risk of outside impurities disrupting the results was minimized.

How Sound Alone Can Lift Matter

The researchers at Argonne National Lab (Argonne) turned to multiphysics simulation and trial-and-error prototyping to optimize the effectiveness of their acoustic levitator. When we want to move an object, sound may not be the tool we would typically reach for. So how does it have the power to float or levitate objects in a lab setting? It’s all about combining forces in just the right way to create lift.

When sound vibrations travel through a medium like air, the resulting compression is measurable and real. By combining acoustophoretic force, gravity, and drag, the pressure is just enough to not only lift a material like liquid medicine, but to also allow the medicine to be positioned, rotated, and moved according to the needs of the operator.

Pressure pockets created by waves between the transducers of the acoustic levitator do the heavy lifting on a particle scale.

Rotating Droplets of Medicine Before They Crystallize

By keeping the droplets in a steady rotation, researchers are able to work on the chemical reactions while the medicine stays liquid and amorphous. This is key for creating a safe, steady environment where medicine will form correctly.

Modeling the Geometry of the Acoustic Levitator

Every material and measurement in the acoustic levitator will change both whether the device works in its final design and how finely it can be adjusted according to the needs of the scientists who use it.

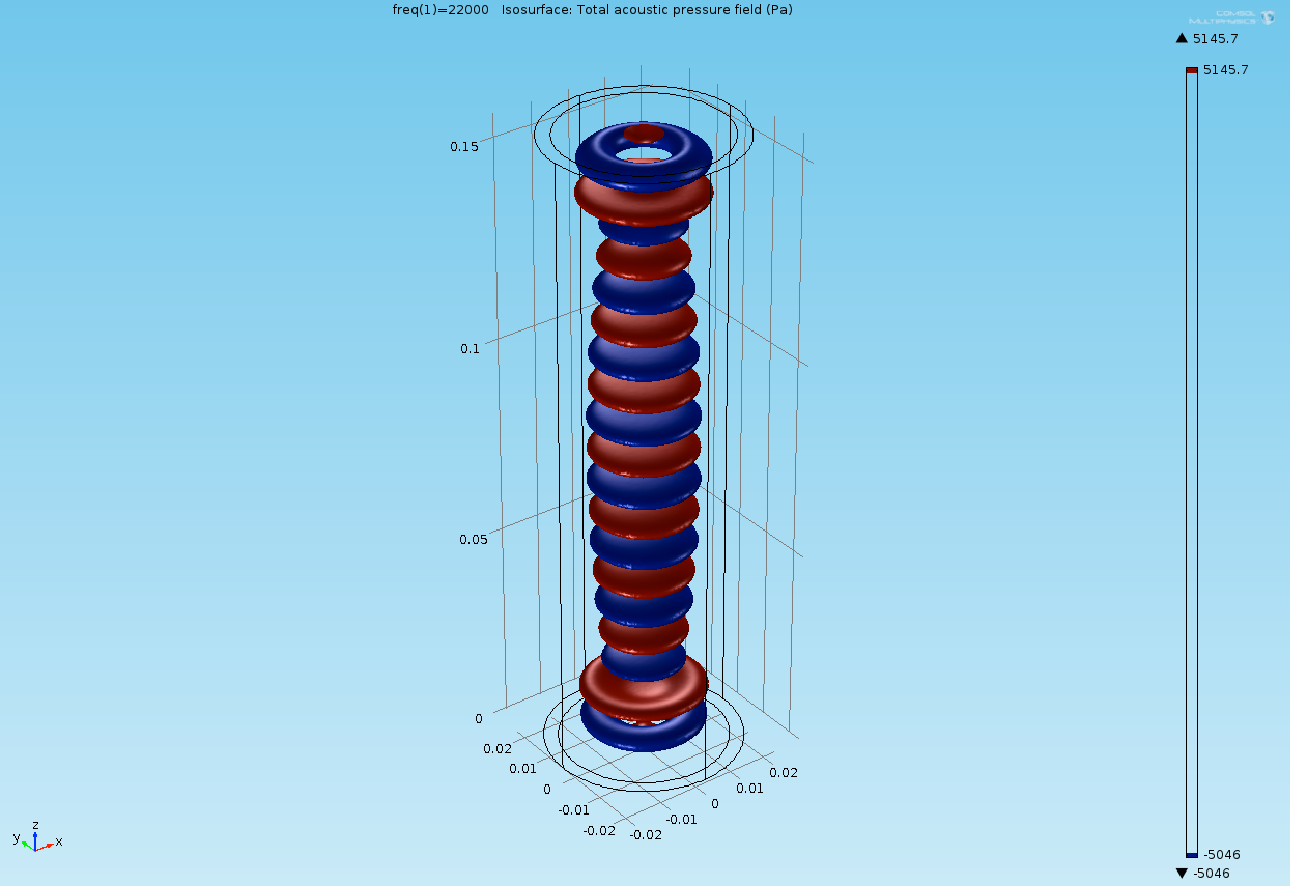

The geometry of the device includes two small piezoelectric transducers that stand like trumpets above and below the working area where medicine is created, like this:

The acoustic levitator’s wave patterns are controlled by pieces of Gaussian profile foam located on evenly-spaced transducers.

Possibly the most important part of the design is the Gaussian profile foam, which consists of polystyrene and coats the ends of each transducer. This foam works to remove acoustic waves that fall outside the required range. It acts as a filter to maintain even, well-defined standing waves.

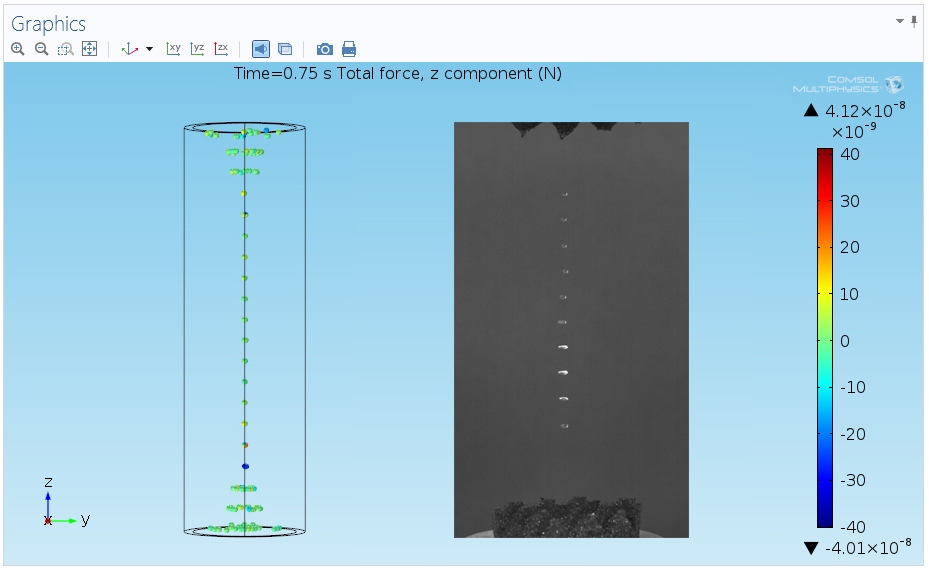

Using COMSOL Multiphysics together with the Acoustics Module, CFD Module, and Particle Tracing Module, the team at Argonne modeled the acoustic levitator. Working cohesively with simulation, they were able to narrow down the shape of the acoustic field and location of floating droplets.

The simulation above shows that at T = 0.75 seconds droplets formed from the particles. On the left, the simulation shows the expected particle distribution and on the right, a photograph depicts the actual distribution of the droplets.

Safer, More Accurate Medicine with Acoustic Levitation

As advances in acoustic levitation expand, the ability to work with finer and finer chemical reactions will allow members of the pharmaceutical science community to expand their reach, perhaps discovering many new medicines with life-saving qualities.

Further Reading

- Learn more about how Argonne improved their acoustic levitation technology.

Comments (4)

Alex Zhang

December 22, 2015This is cool

Alex Zhang

December 22, 2015Really cool. Hope there will a manual for this.

Fleur Naghdi

February 2, 2019Hi.

May I ask you to share related *.mph file?

Brianne Christopher

February 6, 2019 COMSOL EmployeeHello Fleur,

Thank you for the comment! We do not have access to the model featured in this blog post at this time.

Please contact the Support team for questions related to your modeling work.

Online Support Center: https://www.comsol.com/support

Email: support@comsol.com

Thank you!