Noninvasive ventilation (NIV) masks supply air to patients in respiratory distress via continuous positive airway pressure (CPAP). Polibrixia, a research company in Italy, set out to design and optimize an oronasal mask for CPAP- and NIV-ventilated patients using multiphysics simulation. Their goal? To provide more respiratory devices in the global battle against COVID-19.

The NIV Mask: A Design Challenge During a Global Challenge

About 5% of patients affected by the respiratory illness COVID-19 require both hospitalization in intensive care units and ventilatory assistance. However, hospitals in areas experiencing a surge in the spread of COVID-19 often reach capacity and experience limited access to mechanical respirators. In addition, ventilators can cause adverse and long-term side effects, so a noninvasive alternative could spare patients trouble down the road.

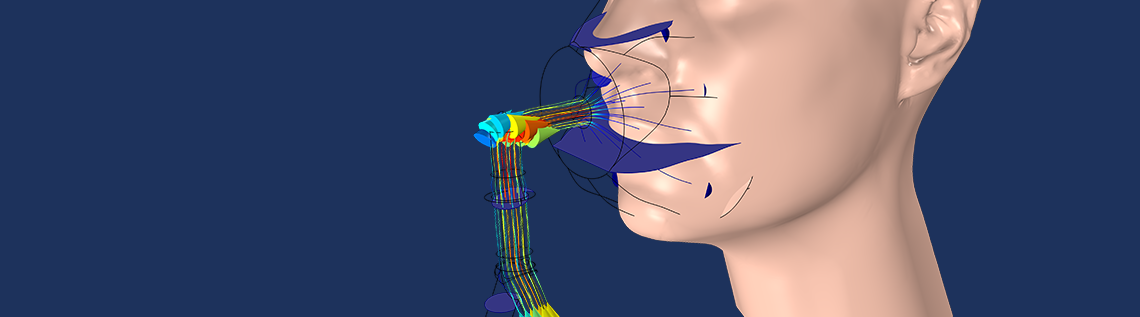

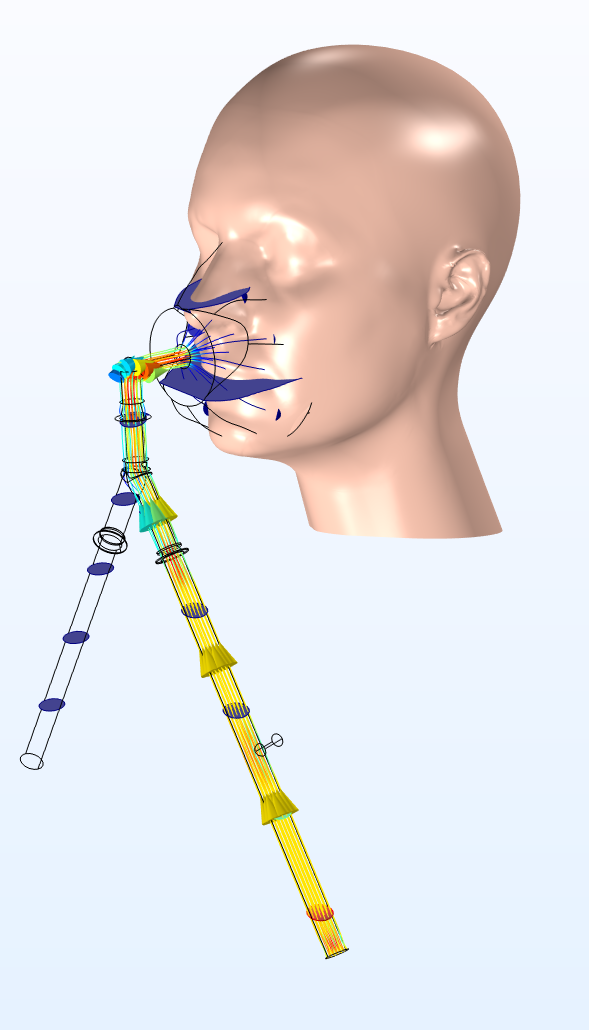

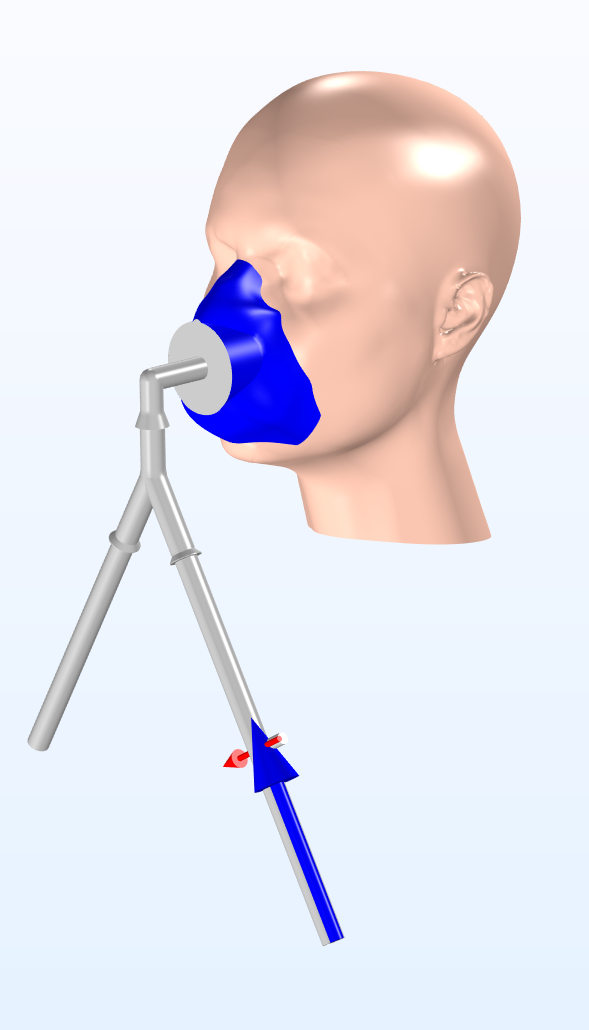

A simulation of an NIV mask in COMSOL Multiphysics®. Image courtesy Polibrixia.

NIV masks offer a form of noninvasive monitoring and ventilation for COVID-19 patients, lessening the need for mechanical respirators like ventilators. To effectively design NIV masks for maximum patient performance, while balancing strict time constraints, Davide Fausti, Maurizio Mor, and Massimo Antonini from Polibrixia in Italy, a COMSOL Certified Consultant, used the structural and fluid flow capabilities of the COMSOL Multiphysics® software.

Structural Analysis of an NIV Mask

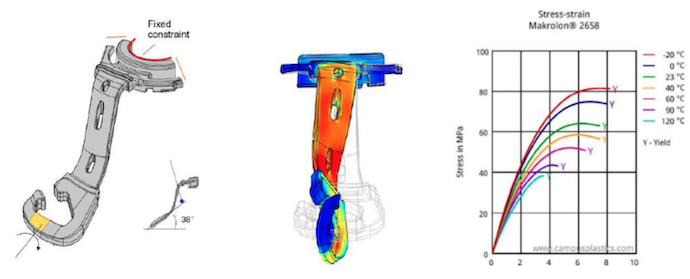

The body of Polibrixia’s NIV mask is made up of Makrolon® 2658, a polycarbonate material. The technical specification sheet of the material only includes data relating to the yield point, but not for the stretch following the yield to the breaking point.

The researchers needed to understand the makeup of the material. To determine the strength and durability, they performed a stress-strain analysis in COMSOL Multiphysics.

Stress-strain analyses of the NIV mask body (left) and polycarbonate material (right). Images courtesy Polibrixia.

CFD and Transport Analysis of Airflow Through an NIV Mask

One of the NIV mask’s main uses is to increase the partial pressure of the oxygen in the lungs and arteries. Each liter of oxygen delivered from the system’s cylinder mixes with ambient air and adds 3–4% of fractional concentration to the mask’s oxygen.

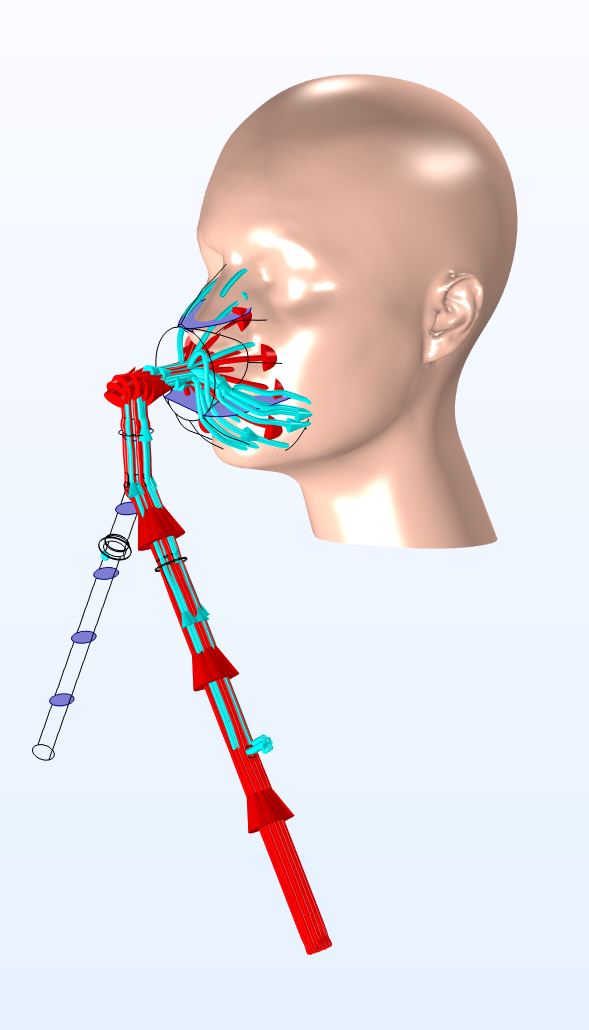

The team used CFD modeling to understand the flow of the oxygen-air mixture in various percentages, simulate different airflow situations, and see the speed range of airflow near the mask.

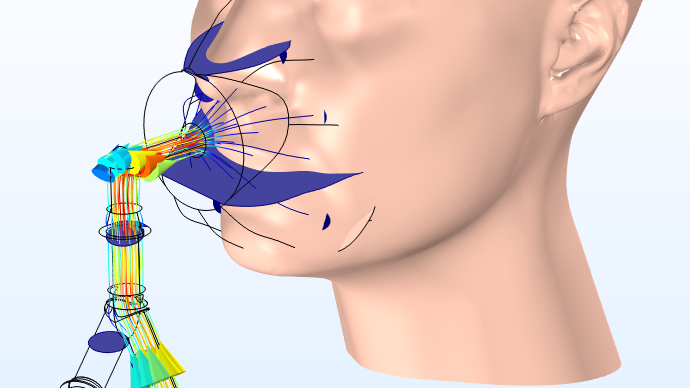

CFD simulation results for the drug dosage levels in the NIV mask. Images courtesy Polibrixia.

The NIV mask setup is also used to dispense drug dosages for treating COVID-19 patients. By modeling transport phenomena, the team could find the objective regular diffusion in the face component of the mask, evaluate drug dosages in the NIV system, and analyze the flow rate of the drug from the outflow of air.

Designing a Life-Saving Device

Responding to the global COVID-19 crisis calls for advanced tools, but it is not feasible to create prototypes for such projects — especially in a period of limited time and resources. Multiphysics simulation can be used to simulate all of the physics involved in an NIV mask system, helping companies like Polibrixia bring life-saving devices to market earlier, and with reduced costs of development.

Makrolon is a registered trademark of Bayer Aktiengesellschaft Corporation.

Comments (4)

Chi Hoon Park

August 17, 2020Dear Christopher, thank you for nice information. Is there a human face model or a body model in COMSOL?

Brianne Christopher

March 15, 2021 COMSOL EmployeeHi Chi Hoon,

Thank you for your comment. This model is not currently available, as it is from customer research.

Best,

Brianne

MUHAMMAD SULEMAN

August 17, 2020Good, but where are the corresponding mathematical models, initial conditions, and boundary conditions.

Brianne Christopher

March 15, 2021 COMSOL EmployeeHi Muhammad,

Thank you for your comment. This model is not currently available, as it is from customer research.

Best,

Brianne