The Passive Vaccine Storage Device (PVSD) is a highly advanced container that combines ingenuity and insulation technology to empower aid workers delivering vaccines to the toughest-to-reach corners of the globe. Designed as a prototype that improves upon earlier models of vaccine transportation devices, this compact apparatus was developed with all the necessary steps: careful planning, simulation, and testing.

The Elements Pose the Greatest Challenge

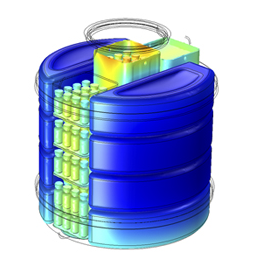

To optimize the Passive Vaccine Storage Device (PVSD), engineers at Intellectual Ventures, as part of the Global Good Program, turned to thermal and vacuum system modeling with COMSOL Multiphysics together with experimentation.

In the early development stages, they began with a design similar to a cryogenic dewar — a specialized vacuum container commonly used in the field. Typical dewars are able to store ice for a few days before it melts, which is not nearly enough time for long trips to remote destinations. Traveling from a source point to areas where people need vaccinations could take weeks depending on their locations. Long travel times in combination with extreme climates present major challenges for experts working in the medical community. The PVSDs need high-performance insulation to create the temperature-controlled environment required for vaccine storage. Each layer of the device can impact overall performance and is designed to add to its insulative strength.

The Passive Vaccine Storage Device can hold vaccines in a temperature-controlled, easy-to-transport compartment for longer durations than ever before.

The shell of the PVSD is made of multilayer insulation, which is similar to the materials used for temperature regulation in spacecraft. This design is especially necessary for areas of the world that get incredibly hot because the vaccines need to stay in a cool and narrow temperature range (between 0°C and 10°C). The multilayer insulation consists of several layers of reflective aluminum, a low conductivity spacer, and nonconducting vacuum space.

When modeling the PVSD, the Intellectual Ventures team considered physics phenomena and design variables including heat transfer, outgassing, and hold time.

Why Do Vaccines Need to Stay Cool?

Vaccines require cold chain storage, which entails proper handling from the moment they are manufactured up until they are administered to a patient. Live virus vaccines can quickly deteriorate as soon as they leave their temperature-controlled space, and inactivated vaccines can lose potency from very short temperature fluctuations. Each year, countless doses of vaccines are thrown away or rendered useless because they were not stored and handled correctly.

The Design That Really Keeps the Cold In

For experimental tests, the researchers used an environmental chamber to recreate extreme outdoor conditions. In addition to experimental evaluation, multiphysics models were implemented using the Molecular Flow Module and Heat Transfer Module with COMSOL Multiphysics to optimize the PVSD design with regard to thermal performance and hold time. The outside of the device, composed of metal, prevents air inflow and helps maintain the cool temperature within. Added rubber absorbs shock to protect the contents during bumpy travels. Inside the PVSD is a small insulating shell (pictured below) that contains several compartments where the life-saving vaccines are stored.

The inner shell of the PVSD holds individual vaccine vials that aid workers can easily access without disrupting the vacuum space or controlled environment.

By breaking down geographical barriers for aid workers, many lives will be impacted by the PVSDs and their important cargo.

Further Reading

- Molecular Flow Module

- Heat Transfer Module

- Read the full-length article “Innovative Thermal Insulation Techniques Bring Vaccines to the Developing World” in the 2014 edition of COMSOL News

Comments (0)