When first introduced, simulation was utilized by just a handful of R&D specialists. Today, a wide community uses simulation to design products, enabling organizations to address complex designs and optimize their workflows. Now, simulation-led design is made even more accessible thanks to several recent developments.

Simulation-Led Design: More Quality, Less Time and Money

In product design, saving time and money without sacrificing quality is a key focus for any organization. Without simulation, it’s more challenging to meet that goal. Traditional workflows involving building and testing physical prototypes are associated with high costs and time-consuming manual efforts.

In simulation-led design, you can test designs in the virtual environment and determine the optimal configuration, rather than address performance failure in prototypes. As a result, organizations can release quality products at a competitive price and speed.

In the past, technological, personnel, and cultural challenges have sometimes prevented organizations from experiencing the benefits of simulation. Recent advancements, however, are changing this. As noted in our white paper “Simulation for the Masses“, written together with Dell, Intel, and Desktop Engineering, transitioning to a simulation-based workflow is becoming a more viable and attainable option.

Hardware and Simulation Software Developments Promote Speedup

Over the years, affordable computing power has become more widely available. With the addition of cores, higher capacity memory, and support for parallel processing, modern workstations are equipped with the horsepower and capabilities needed to run complex simulation studies.

COMSOL Multiphysics® simulation software has been optimized to support these hardware advancements. With the software’s hybrid modeling feature and Floating Network License (FNL), you can run larger simulations on standard workstations designed to support parallel processing and on as many cores and nodes as you would like on a cluster.

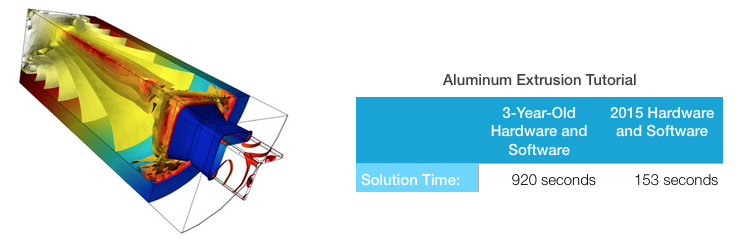

Here at COMSOL, we conducted a benchmark study to compare modern COMSOL Multiphysics® software on a present-day Dell™ computer workstation to a standard hardware and software configuration from three years ago. Why three years? That’s the typical time frame in which an organization will consider upgrading their hardware and/or software. Our findings showed dramatic improvements in modern-day hardware and software configurations, with simulation speeds found to be up to six times faster.

In the three-year-old hardware and software, the solution time for this aluminum extrusion tutorial was 920 seconds. In the modern hardware and software, its solution time was 153 seconds.

Simulation Apps Are Spreading Simulation Capabilities

With the hardware and simulation power in place, simulations can be run at quicker speeds, thus delivering faster results. This can still mean a rather heavy workload for the simulation expert, who is often relied upon to test each new modification to a design. The Application Builder in COMSOL Multiphysics (version 5.0 and higher), however, is revolutionizing the simulation workflow, empowering more people to run their own simulation tests using apps.

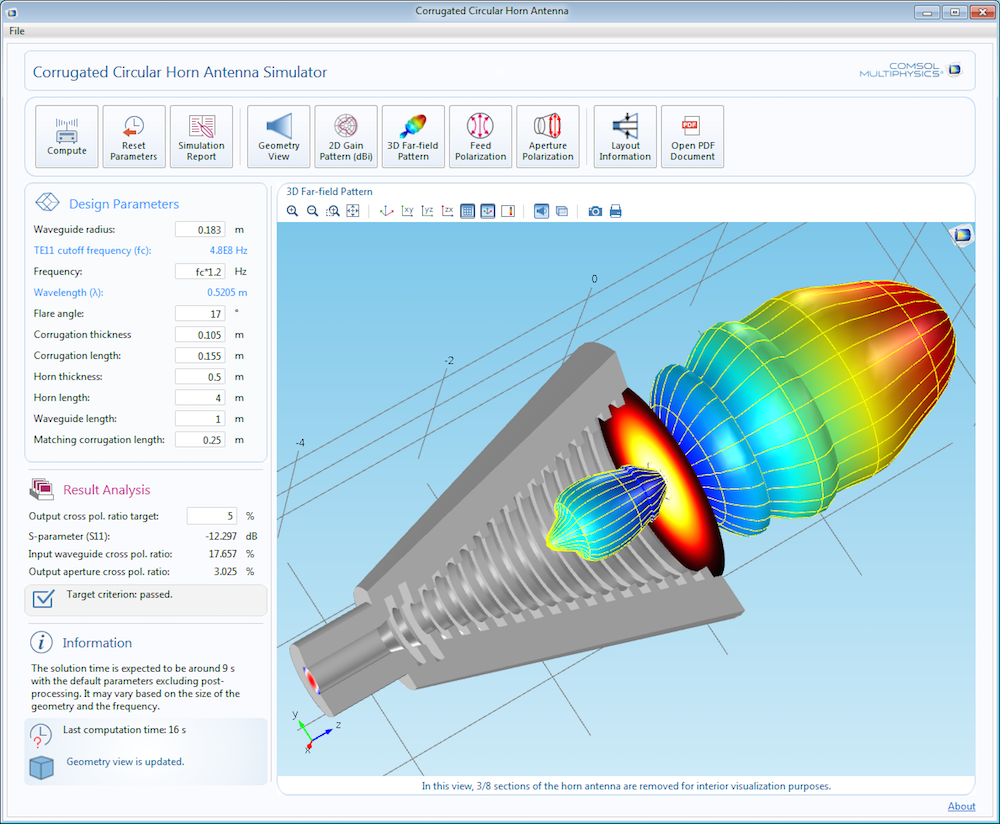

Simulation apps feature an easy-to-use interface and can be customized to include those parameters that are relevant to your particular design analysis. App users can then modify these parameters based on their updated design configurations, obtaining their own simulation results. This approach not only helps lighten the workload for the simulation expert, but it also promotes a more collaborative approach to simulation research — one that provides more accurate and efficient results.

Our demo app of a corrugated circular horn antenna.

COMSOL Server™ license further simplifies the distribution of simulation apps. Once uploaded to this platform, apps can be run in any major web browser as well as in a dedicated desktop client. They can be also accessed on a variety of devices, from tablets and desktops to workstations and clusters.

Greater Recognition for Simulation’s Advantages

In product design, the complexity of products continues to grow, while time-to-market decreases. To better meet these demands, more and more organizations are expressing an interest in transitioning to simulation-led design. Moving from a traditional workflow to a simulation-based workflow is, of course, a large undertaking that requires several steps.

It is important to first educate people throughout your organization, from the executive level to grassroots, on the benefits of simulation. Demonstrating the ways in which simulation can enhance innovation as well as its ease of use can help foster acceptance of this new workflow. Calculating its return on investment — consider using our benchmarking study as a starting point — and enlisting the support of executive leadership are also effective techniques for speaking to the advantages of simulation-led design and generating acceptance.

Read the Free White Paper to Learn More

Dell is a trademark of Dell Inc.

Comments (0)