Cooling and Solidification of Metal

Application ID: 12701

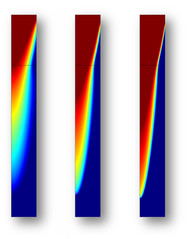

This example is a model of a continuous casting process. Liquid metal is poured into a mold of uniform cross section. The outside of the mold is cooled and the metal solidifies as it flows through. When the metal leaves the mold, it is completely solidified on the outside, but still liquid inside. The metal will continue to cool and eventually solidify completely, at which point it can be cut into sections. This model is simplified somewhat by not computing the flow field of the liquid metal, it is assumed that the velocity of the metal is constant throughout. The phase transition from molten to solid state is modeled via a temperature dependent specific heat. Issues of convergence and mesh refinement are addressed for this highly nonlinear model.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® and

- either the Heat Transfer Module, Porous Media Flow Module, or Subsurface Flow Module

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.