Friction Stir Welding of an Aluminum Plate

Application ID: 461

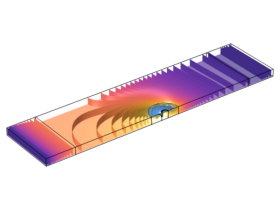

In friction stir welding, a rotating tool moves along the weld joint and melts the aluminum through the generation of friction heat. The tool’s rotation stirs the melted aluminum such that the two plates are joined.

In this model, two aluminum plates are joined by generating friction heat with a rotating tool. Heat is transferred by conduction from the tool into the plates. The movement of the tool is taken into account using a convective heat flux term. The plate surfaces are cooled through free convection and surface-to-ambient radiation.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.