Inkjet Nozzle — Level Set Method

Application ID: 1445

Although initially invented to be used in printers, inkjets have been adopted for other application areas, such as within the life sciences and microelectronics. Simulations can be useful to improve the understanding of the fluid flow and to predict the optimal design of an inkjet for a specific application.

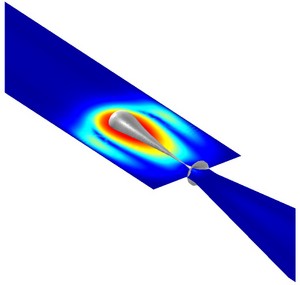

The purpose of this application is to adapt the shape and operation of an inkjet nozzle for a desired droplet size, which depends on the contact angle, surface tension, viscosity, and density of the injected liquid. The results also reveal whether the injected volume breaks up into several droplets before merging into a final droplet at the substrate.

The fluid flow is modeled by the incompressible Navier-Stokes equations together with surface tension, using the level set method to track the fluid interface.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® and

- either the CFD Module, Microfluidics Module, Polymer Flow Module, or Porous Media Flow Module

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.