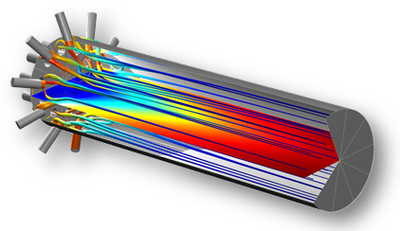

Polymerization in Multijet Tubular Reactor

Application ID: 3831

In a polymerization reactor for polyester manufacturing, the mixing in the reactor is achieved by impinging turbulent jets of reactants onto each other. The turbulence affects the reaction kinetics and quality of the polymer linkage.

Turbulent flows involving rapid reaction kinetics are quite common in the production of polymers, and the complex interplay between fluid dynamics and fast chemical reactions can significantly impact reactor performance. This can noticeably affect conversion and yield, while also influence the average length of polymer chains, the molecular weight distribution, cross-linking, and chain-branching.

In this example, a full 3D model is employed where the detailed effects of fluid dynamics and reactor geometry are taken into account.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® and

- Chemical Reaction Engineering Module and

- either the CFD Module, or Heat Transfer Module

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.