Slider Crank Mechanism with Joint Clearance

Application ID: 89951

Joints between two components of a mechanical system are sometimes not perfectly fitting. For the ease of assembly and to allow relative movement between the components, a small gap called clearance is provided between the joining components. The presence of clearance on joints can sometimes adversely affect the performance of the system by generating impact forces thus giving rise to noise and vibrations.

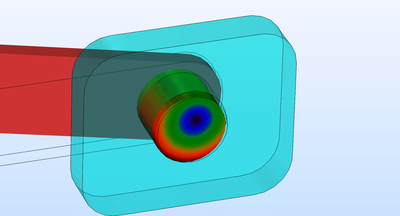

This model compares the performance of a slider crank mechanism with and without a joint clearance. All components of the mechanism are assumed rigid. Hinge Joint node is used when there is no clearance on a joint whereas Clearance Joint node is used to include clearance on a joint. A transient analysis is performed to analyze the effect of joint clearance on slider velocity, slider acceleration, and crank moment. In addition to this, the dynamics of journal within the bearing and the reaction force in the clearance joint are also analyzed.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.