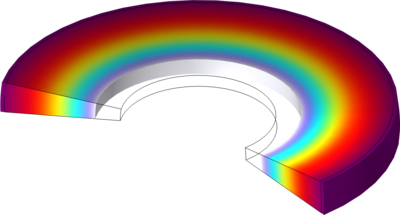

Thermally Induced Creep

Application ID: 207

Creep is an inelastic time-dependent deformation which occurs when a material is subjected to stress at sufficiently high temperature, say 40% of the melting point or more.

Experimental creep data (using constant stress and temperature) often display three different types of behavior for the creep strain rate as function of time:

- In the initial primary creep regime the creep strain rate decreases with time.

- In the secondary creep regime the creep strain rate is almost constant.

- In the final tertiary creep regime the creep strain increases with time until a failure occurs.

This model computes the stress history over a long time for a material that exhibits creep behavior. The model is taken from NAFEMS Selected Benchmarks for Material Non-Linearity. The displacement and stress levels are compared with the values given in the reference.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® and

- Nonlinear Structural Materials Module and

- either the MEMS Module, or Structural Mechanics Module

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.