Simulation for Food Engineering Innovation

Engineers and researchers working in the food and beverage industry benefit from incorporating the COMSOL Multiphysics® simulation software into their workflow to model products, processes, and devices that are challenging or resource intensive to test physically. Simulation is also useful for proposing new and optimizing existing designs and accelerating the prototyping process.

The COMSOL Multiphysics® software features a consistent user experience, regardless of engineering application and physics phenomena. The platform includes the Model Builder for creating simulations from geometry to visualization, and the Application Builder and Model Manager to further support collaboration across teams and organizations.

Real-World Food Engineering Simulation Examples

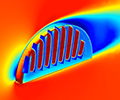

Refrigeration Technology

Engineers at thermofin GmbH use simulation to design cold storage rooms and to optimize heat exchangers for air conditioning and refrigeration systems.

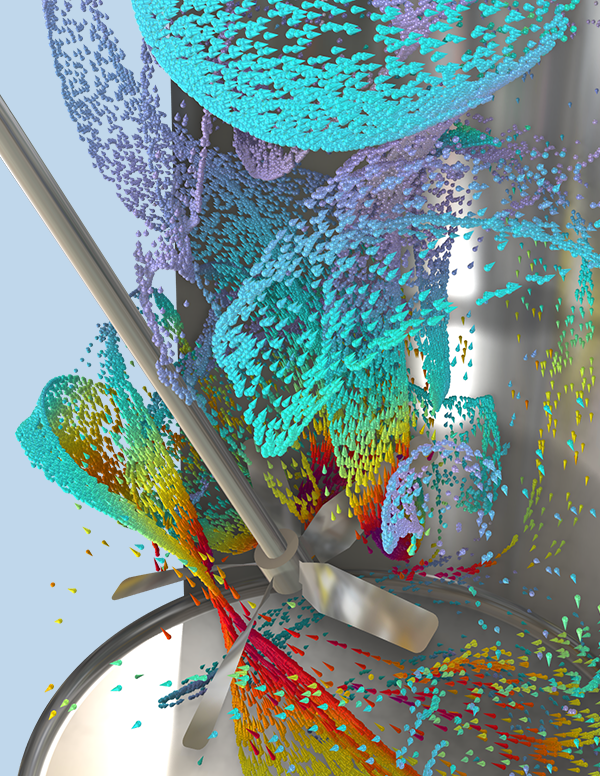

Production Processes

The team at Nestlé Product Technology Centre optimized and streamlined their chocolate bar production process with the help of multiphysics simulation.

Commercial Appliances

Illinois Tool Works (ITW) Food Equipment Group designed "smart" solid-state commercial microwave ovens that are more efficient and provide more uniform heating.

Drying Processes

A senior scientist of Empa shares how multiphysics modeling provided insight into various convective drying processes for soft cellular materials.

Food Safety

Researchers at Cornell University built simulation applications to run what-if scenarios and study food products from a safety perspective.