A Flow and Transport Model for Low-Temperature Gaseous Nitrocarburizing of Stainless Steels

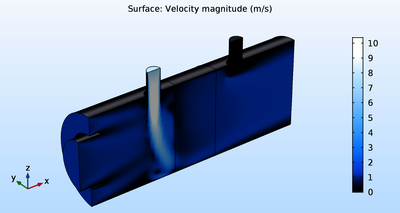

An integrated numeric, thermodynamic, and experimental analysis work was conducted to find out the proper flow and transport parameters of combined chemical species for low-temperature gaseous nitrocarburizing of stainless steels in an industrial furnace built for thermochemical treatments. Such parameters are responsible for a steady thermochemical atmosphere essential for the anti-passivation on the surface of stainless steels. The corrosion resistance of stainless steel arises from a dense chromium-rich oxide layer that forms naturally and prevents diffusion of interstitial species into the base materials. To remove the passive layer, required interrelated partial pressures of combined gaseous chemical species were calculated thermodynamically. These calculated data were coupled with purge cycles simulated with COMSOL Multiphysics® and transformed to applicable processing parameters. A flow and transport model was built to solve turbulent gas flow and transport, and heat transfer and equilibrium during the purge cycles. Finally, the simulated results were confirmed by experimental measurements. It has been proved that numeric simulation with the posted flow and transport model can assist the industrial thermochemical treatments and effectively remove the passive layer of stainless steels.

Acknowledgement This work was sponsored by the AiF under the ZIM program, grant No. KF 2126912KM4.

Download

- feng_presentation.pdf - 1.52MB

- feng_paper.pdf - 0.66MB

- feng_abstract.pdf - 0.01MB