Modelling Thermal Capillary Effects and Flow in the Molten Pool During Selective Laser Melting

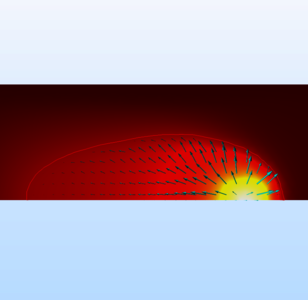

Laser additive manufacturing has become an interesting field of engineering which is revolutionizing industrial processes. Selective Laser melting (SLM) is a widely used additive manufacturing technique for 3D printing of metal structures. This process has a particular complexity in modeling and simulation due to multiple phenomena taking place in a large range of temperature; from room temperature to thousands of degrees. Currently, different SLM models have been proposed. Some can be used for only a further understanding of the process, others can even be used in an attempt to predict and optimize SLM parameters for optimal printing. In the latter case, the size and geometry of the molten pool are the main information leading to knowing whether the printed material is fully molten or not. Temperature profile, temperature gradient and cooling curves are also useful information that can help in a qualitative prediction of the micro-structure and solid phases in the printed material. However, in this modeling challenge, many people tend to use the most simplified way eliminating the fluid dynamics in the molten pool. In this work, we present a way to use COMSOL Multiphysics to model thermal capillary effects and fluid flow inside the molten pool in a single scan or multiple scan model of SLM. The velocity field in the molten pool is simulated and analysis of its impact on other thermal parameters can be discussed. Efficient way to capture other optical and thermal phenomena involved is also presented.

Download

- tan_presentation.pdf - 1.17MB

- tan_paper.pdf - 1.05MB

- tan_abstract.pdf - 0.07MB