Numerical Optimization of Active Heat Sinks Considering Restrictions of Selective Laser Melting

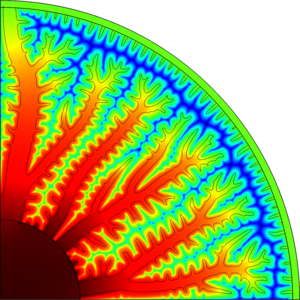

Parametric and topology optimization approaches are widely used techniques for performance improvement of components in terms of various objectives. Especially topology optimization often leads to complex geometries that are difficult or impossible to produce by conventional manufacturing processes. Due to its great freedom in shape and structure design, additive manufacturing methods like selective laser melting are predestined for the production of such components. Nonetheless some restrictions need to be considered while designing parts for additive manufacturing to ensure for example the printability or the possibility to remove support structures. In this paper, an optimized design of an active heat sink is sought. The goal of the optimization is the maximization of the thermal conductivity, hence the minimization of the temperature of the heat dissipating component. Therefore, a parametric as well as a topology optimization is implemented in COMSOL Multiphysics® and compared to each other in terms of performance improvement and computational effort. Since a two-dimensional problem is considered the heat transfer in solids module in combination with the optimization module is used for the calculations. Manufacturing restrictions are included into the simulations to directly obtain printable components granting a reduction of post processing effort. Limitations of such restrictions are shown and approaches to handle these limitations are investigated. Experiments with 3D-printed prototypes are carried out in order to validate the numerical results. In comparison a conventional heat sink is investigated to show lightweight potentials and possibilities of performance improvement.

Download

- lange_poster.pdf - 4.06MB

- lange_paper.pdf - 10.88MB

- lange_abstract.pdf - 0.04MB