Reciprocating Flow Applied For Liquid-cooling-based Battery Thermal Management System

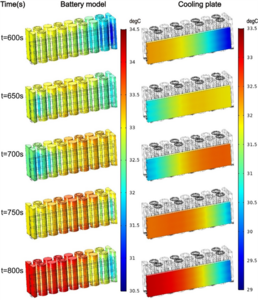

Liquid cooling is the most popular battery thermal management system (BTMS) at present, while suffers from high energy consumption and high temperature difference between upstream and downstream. Herein, we first use a reciprocating liquid flow-based BTMS (RLF-BTMS) for cylindrical batteries to release those issues. The comparison among unidirectional flow, crossdirection flow, and reciprocating flow was carried out to investigate the effectiveness of reciprocating flow. After that, the effects of velocity and reciprocating period, two key factors of reciprocating flow, were systematically explored. Finally, a comprehensive criterion of the performance of BTMS considering maximum temperature, temperature difference, temperature distribution coefficient, and energy consumption was proposed to optimize the reciprocating flow. The temperature difference and energy consumption are reduced by 55.3 % and 15.6 % through reciprocating flow. To get energy-saving performance, the reciprocating flow velocity ought to be lower than 0.085 m/s. Since has been greatly reduced, temperature difference changes insensitively with velocity. As decreased from unidirectional flow to 0, the reciprocating periods are divided into three stages: disorder stage, positive stage, and worse stage, according to the thermal characters. Based on the novel BTMS evaluation index, 0.05 m/s and 200 s are selected as the optimal velocity-period combination for the RLF-BTMS. This study recommends applying reciprocating flow to replace the traditional unidirectional flow to get better cooling performance.