Sensitivity Analysis of CPP’s for Solvent Removal Process of a API-Protein Bonded Nano-Suspension

Solvent extraction and evaporation is a widely used unit operation in the manufacturing of micro and nano-particles.

Due to the weak bond of the API to the protein, the product is highly sensitive to temperature, mechanical mixing and extraction/evaporation rate. A slow extraction/evaporation rate leads to changes of the particle size, which may result in blockage of the sterile filter and failure of the batch. In situations similar to this one, mathematical modeling is becoming a promising tool to improve the understanding and control of the CPP’s and reduce the development time and cost.

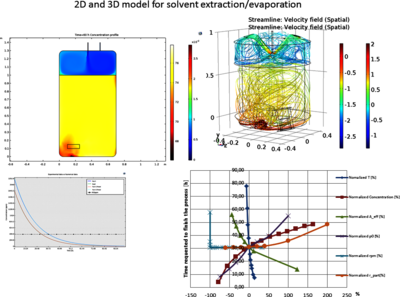

The purpose of this work is to determine the sensitivity of different process parameters related to the solvent extraction/evaporation unit operation. A mathematical model was developed and applied to predict the duration required to accomplish the solvent extraction/evaporation process.

Turbulent Flow and Rotating Machinery physics interfaces in the CFD Module of COMSOL Multiphysics® were used to determine the stationary velocity profile of the air inlet through an air distributor and the mixing of the nano-suspension in the reactor. The Transport of Diluted Species interface was used and coupled with a Multiphysics interface to describe the mass transfer of the solvent from the nanoparticles to the liquid solution and solvent evaporation at the air/liquid interface.

The influence of temperature, pressure, surface area, particle size of the suspension, stirring speed and air flow rate on the solvent evaporation were investigated, and the critical aspects of these parameters was plotted to determine the most critical process parameters and to have a better control on the process.

The model showed good fit with experimental data, thus is able to provide a supportive information to enhance the decision making.

Download

- huang_presentation.pdf - 1.57MB

- huang_poster.pdf - 0.74MB

- huang_abstract.pdf - 0.16MB