Transient Analysis of a Finned, Cylindrical Adsorber Reactor in Solar Adsorption Refrigeration

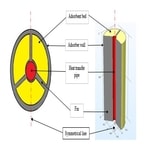

Solar-powered adsorption refrigeration system is an excellent application of solar thermal energy, with a matching of peak cooling demands with the availability of solar radiation. This green technology in cooling productions reduces the dependency on fossil fuels in energy generation, and consequently the global warming. In this study, the solar adsorption refrigeration cycle operates using activated carbon-methanol working pair. The adsorber reactor replaces compressors in the refrigeration cycle, which promises a reduction in electrical consumption. However, the system suffers low performance problem in terms of coefficient of performance (COP) which makes them a step back of commercialization. This problem is caused by the low heat transfer inside the adsorber reactor, which consequently leads to poor mass transfer. Thus, the objectives of this study are to increase the system performance by enhancing the heat and mass transfer inside the adsorber reactor. A simulation study of optimizing the adsorber reactor to enhance its performance is performed in COMSOL Multiphysics. A time-dependent analysis on a three-dimensional model is built. A stainless-steel, cylindrical geometry is modeled for the adsorber reactor. In the middle inside the adsorber reactor, a thin cylindrical heat transfer pipe is modeled to supply heat energy for desorption process, and cold water for adsorption process. Two rectangular aluminium alloy fins are attached inside the adsorber reactor. For modeling simplicity, the model is then reduced into a quarter. The first physics interface is the heat transfer in porous media by convection and conduction between heat transfer pipe and adsorber reactor. The heat flux from the heat transfer pipe is the boundary conditions with external forced convection into adsorber reactor during desorption process. On the other hand, a reverse process is set for an adsorption process. In the optimized cylindrical finned-tube adsorber reactor which starts by adding two fins, the heat transfer in solid fins is by conduction. Different fins thickness are used in each simulation. After finish one simulation study, the number of fins are increased and is simulated with different fin thickness respectively, until the number of fins reached 14. Finally, the adsorber reactor model is meshed with an ‘extremely fine’ mesh to ensure a high number of element and degree of freedom. A transient analysis on the simulation results are then performed to evaluate the coefficient of performance of the systems with different fins configurations. A uniform temperature distribution inside the adsorber reactor shows a good heat transfer process, thus induced good mass transfer of the refrigerant. The simulation results are analyzed to evaluate the optimum fin configurations with improved transient behavior and obtain the highest performance. From the optimization works of adsorber reactor with fins configurations, it is expected that more fins improve heat transfer within adsorber reactor bed. As a result, COP is improved. However, too many fins configuration reduce the COP since extra heat is required to change the fin material temperature.

Download

- tan_abstract.pdf - 0.02MB

- 9. norhafizah_binti_ahmad_junaidi_presentation.pdf - 2.94MB