Over the past few decades, countless foods and beverages have hit grocery store shelves only to be discontinued in a few years’ time. You may even be able to think of a favorite snack or drink of yours that seemingly disappeared out of nowhere. This food vanishing act can be explained with a very simple answer: If a product isn’t selling, the chances of it being restocked aren’t in its favor.

In this blog post, we’ll explore how previously failed products and the use of multiphysics simulation can inspire the creation of innovative appliances, products, and processes within the food industry.

Food Products That Succeeded by Failing

Discontinued or failed products aren’t necessarily a bad thing, and here’s why: A lot can be learned from their downfall and they can inspire ideas that lead to bestsellers. One example of this is the origin story of the American breakfast cereal Wheaties®. In the early 1920s, an employee of the Washburn Crosby Company, known today as General Mills, was preparing a wheat bran mixture. In the process, they accidentally dropped a portion of the semiliquid mixture onto a hot stove top, and it quickly crisped into a flake. (Ref. 1) Thus, Wheaties®, as we know it today, was born. But the story doesn’t end there. The flakey cereal was far from an overnight success — it was a failing product for many years after its debut in 1924. It eventually became a household name after an advertising jingle about the cereal was played on radio stations across the U.S. The cereal’s fame was further exemplified thanks to its close association with the sports world. (More than 850 athletes are depicted on the cover of Wheaties® boxes.)

Another similar failure-to-success story in the food industry is the story behind the invention of the microwave oven. Like Wheaties®, the microwave oven was also an accidental discovery. While working in a lab testing a magnetron, physicist and inventor Percy Spencer noticed that a peanut cluster bar in his pocket began to melt. To further investigate the magnetron’s cooking abilities, Spencer exposed popcorn kernels and an egg to it. He found that the popcorn popped and the egg exploded. These observations led Spencer to come to the conclusion that the low-density microwave energy produced from the magnetron was not only heating the food, it was heating it fast. In 1945, Spencer and his employer, Raytheon, patented an invention based on this finding, which they called “Radarange”.

Radarange on a ship. Image by Acroterion — Own work. Licensed under CC BY-SA 3.0, via Wikimedia Commons.

Early versions of Radarange failed to take off in success due to its size, price, and weight. (It was larger than a refrigerator, cost more than $50,000 in today’s currency, and could weigh over 750 pounds!) With significant modifications made to its design, it became more practical for household use, and sales for the invention, which became known as the microwave oven, skyrocketed. Today, over 90 percent of U.S. households own a microwave oven, which contains technology based on the findings of Percy Spencer.

These stories teach us that it’s important to learn from and build upon our failures and stay inspired. One way to do this is through the use of simulation, which makes it easy to optimize old designs and test new ones. Next, we’ll take a look at what’s possible with the use of simulation in the food industry.

Simulation in the Food Industry

The use of simulation enables engineers and researchers to gain valuable insight into the performance of the product, process, or device that they are studying. With simulation, users can test parameters that are challenging — or even impossible — to test physically. They can also use simulation to propose new designs, optimize devices, and accelerate the prototyping process. The sensitivity of the product quality to different parameters can be studied to achieve a reproducible product. The in-depth understanding of a product, process, or device that simulation provides is especially important for engineers working in the food industry because the production of food products requires close attention to detail. A small change in a food product’s properties can be detected by consumers’ olfaction and gustation senses, which are used for smelling and tasting, respectively.

With the COMSOL Multiphysics® software, engineers can analyze the variety of physics phenomena that impact food products (including heat transfer, fluid flow, chemical reactions, solid mechanics, and electromagnetics) all in one intuitive software environment. This versatility makes COMSOL Multiphysics a platform that can benefit all stages of the food production chain, including production, processing, distribution, retail, and restaurant. In the following section, we’ll explore five concrete examples that highlight the benefit of using simulation in the food industry.

Tutorial Model Examples

COMSOL Multiphysics and its add-on modules contain functionality for modeling a wide variety of processes, industry equipment, and residential appliances that are commonly used in the food and beverage industry. Let’s go over a few of the many examples…

Processes

Freeze Drying

Freeze drying, a process for drying heat-sensitive materials, is used in a wide variety of industries, from the pharmaceutical industry for the preservation of antibiotics and vaccines to the document restoration industry for the restoration of water-logged books, artwork, photographs, and more. However, this process is most widely known for its usage in the food industry for its ability to preserve food products for up to 30 years. When a material, like food, is freeze dried, it is first frozen, and then it is directly turned into a gaseous state through a process called sublimation. In a previous blog post, we discuss how a phase diagram can show how a solid can skip the liquid phase and pass directly into the gaseous stage.

A close-up image of freeze-dried coffee. Image by Pleple2000 — Own work. Licensed under CC BY-SA 3.0, via Wikimedia Commons.

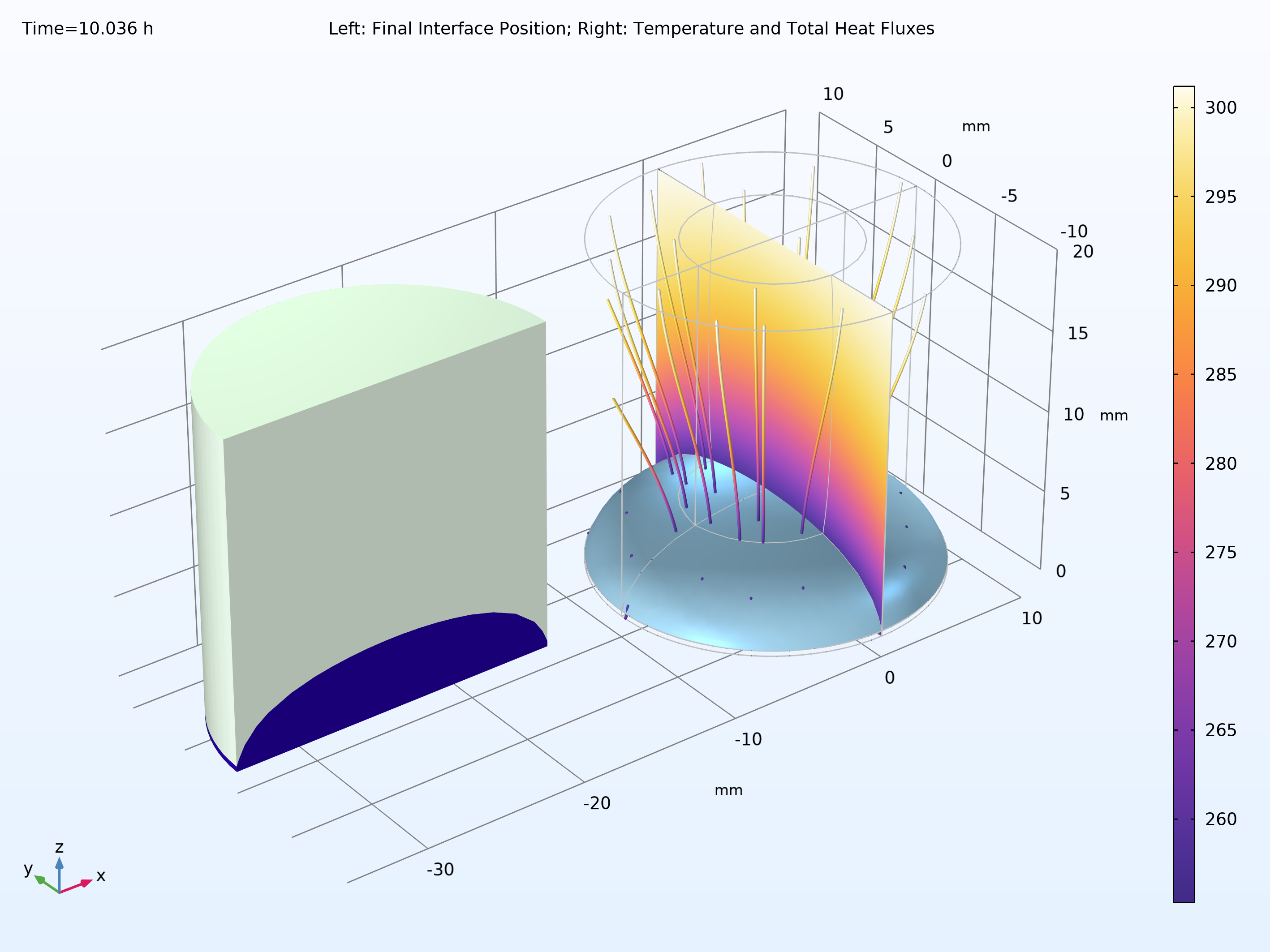

To gain an in-depth understanding of the freeze-drying process, you can model and analyze it with heat transfer simulation. For example, using features and functionality in COMSOL Multiphysics and the add-on Heat Transfer Module, you can model the sublimation of ice through a porous medium in a vial under vacuum-chamber conditions, a common test case for many freeze-drying setups. Gain step-by-step instructions on how to do so using our Freeze-Drying tutorial model.

An image of the Freeze-Drying model.

Fermentation in Beer Brewing

Another process used in the food and beverage industry is the fermentation process, which is often used for the production of beer. During the beer brewing process, fermentation is used to convert the sugar in wort to ethyl alcohol and carbon dioxide gas, which in turn gives beer its alcohol content and carbonation. This process begins when cooled wort (< 20°C) and yeast are added to a fermentation vessel, commonly a closed tank under anaerobic conditions. This action results in the fermentation of the wort. When the fermentation is finished, we are left with the product of beer. (Tip: Learn more about the fermentation process in our blog post “Modeling Fermentation in Beer Brewing Yields a Better Product”.)

A group of fermentation vessels. Image by Antoine Taveneaux — Own work. Licensed under CC BY-SA 3.0, via Wikimedia Commons.

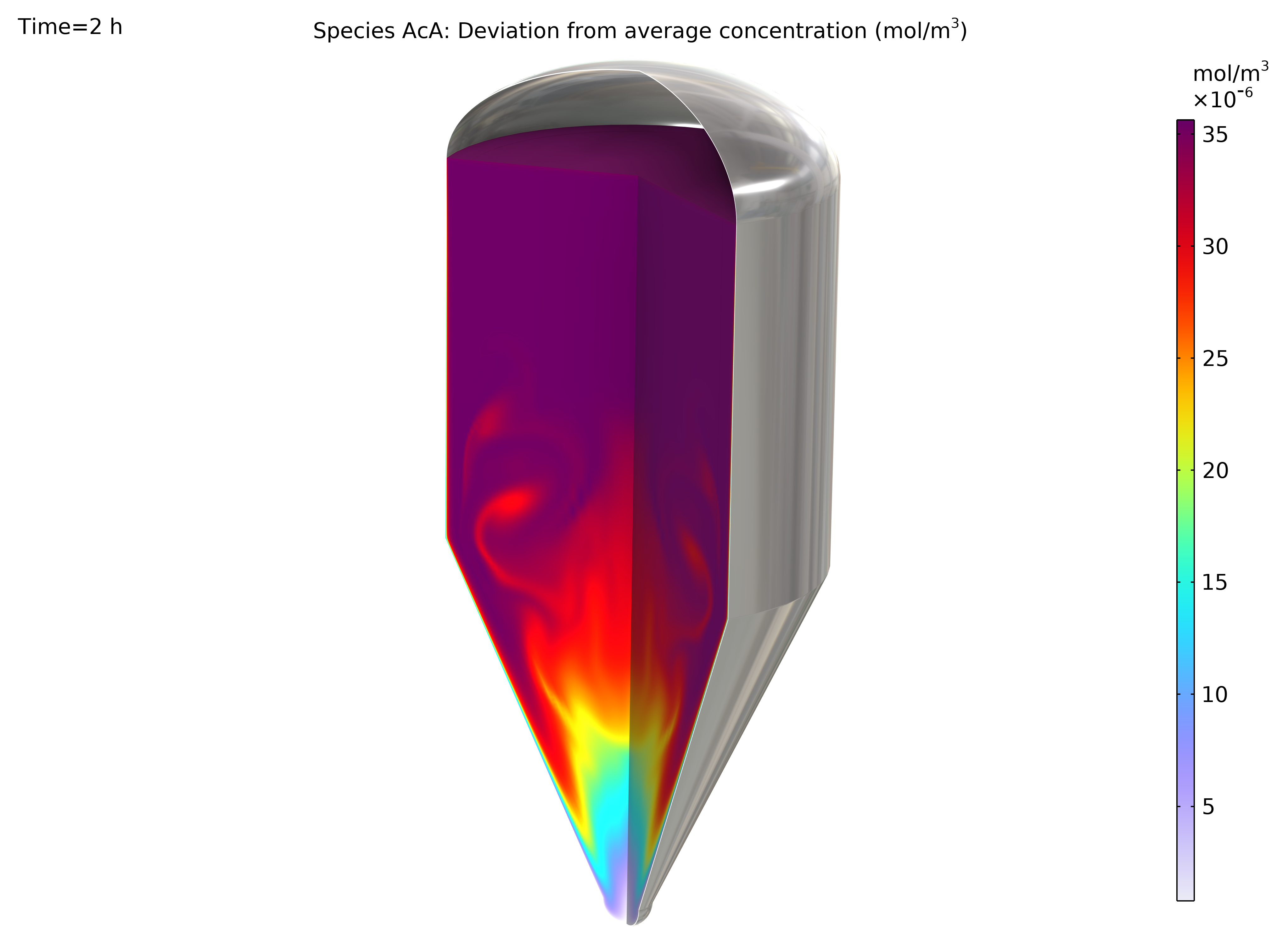

The outcome of the fermentation process can be unpredictable, as it relies on many different factors, including the initial sugar content, yeast type, and chosen process temperature. With the Fermentation in Beer Brewing tutorial model, you can further analyze this process and better predict its outcome with chemical modeling. This tutorial models the fermentation process in two steps. In step one, the fermentation process is modeled in a perfectly mixed tank using the Reaction Engineering interface. In step two, the model is expanded into a spheroconical tank geometry that accounts for mass transfer, heat transfer, and natural convection. Both models enable the evaluation of a variety of parameters that can affect the final alcohol content produced from the fermentation process. See the MPH file and PDF instructions for this model here.

Local deviation from average concentration in a beer fermentation reactor. The model gives an understanding of the sensitivity of the product to the local temperature and flow in the fermentation reactor.

Industry Equipment

Mixers

In the food industry, industrial mixers are used to combine two or more separate ingredients to produce a wide variety of foods and beverages, including, but not limited to:

- Candy

- Chewing gum

- Coffee

- Dressings

- Juices

- Sauces

- Soups

- Syrups

These machines play a key role in determining a food product’s properties, such as its taste and texture, both of which, as mentioned earlier, can easily be detected for change by consumers. Therefore, it is very important that mixers perform efficiently and consistently from batch to batch. (In most cases, they are not only mixers; they are also reactors.) Simulation can be used to design mixers that produce high-quality, uniform, and safe-to-consume products, all within a timely fashion.

An industrial mixer. Image by Erikoinentunnus — Own work. Licensed under CC BY-SA 3.0, via Wikimedia Commons.

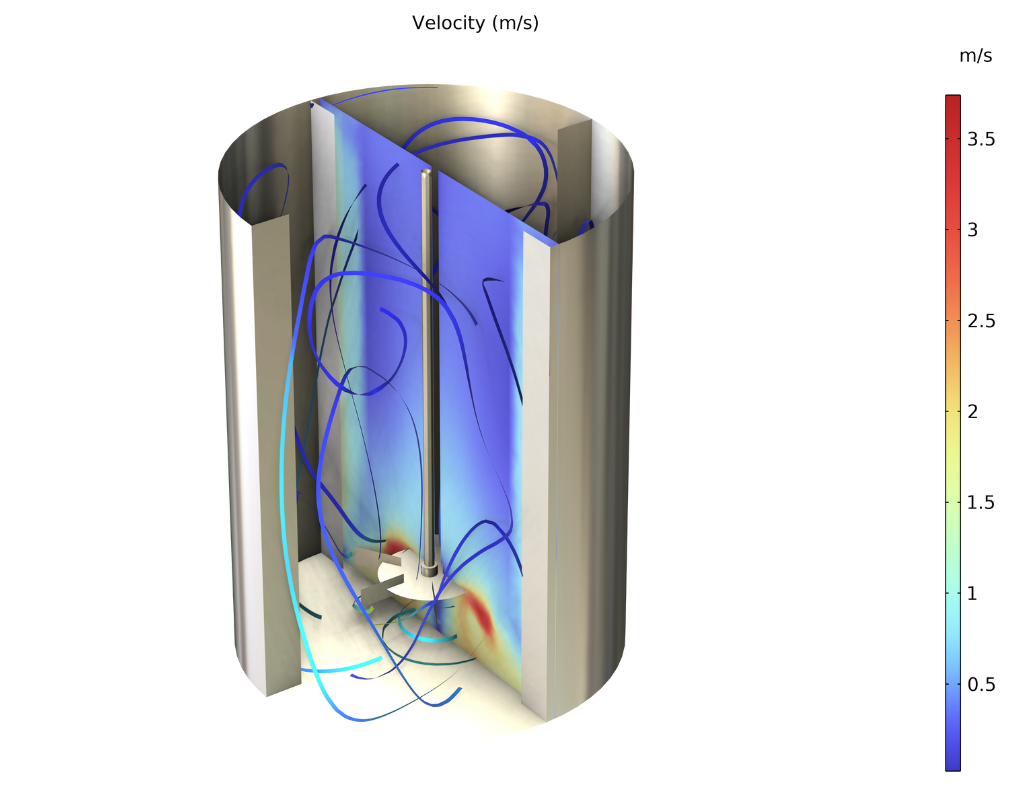

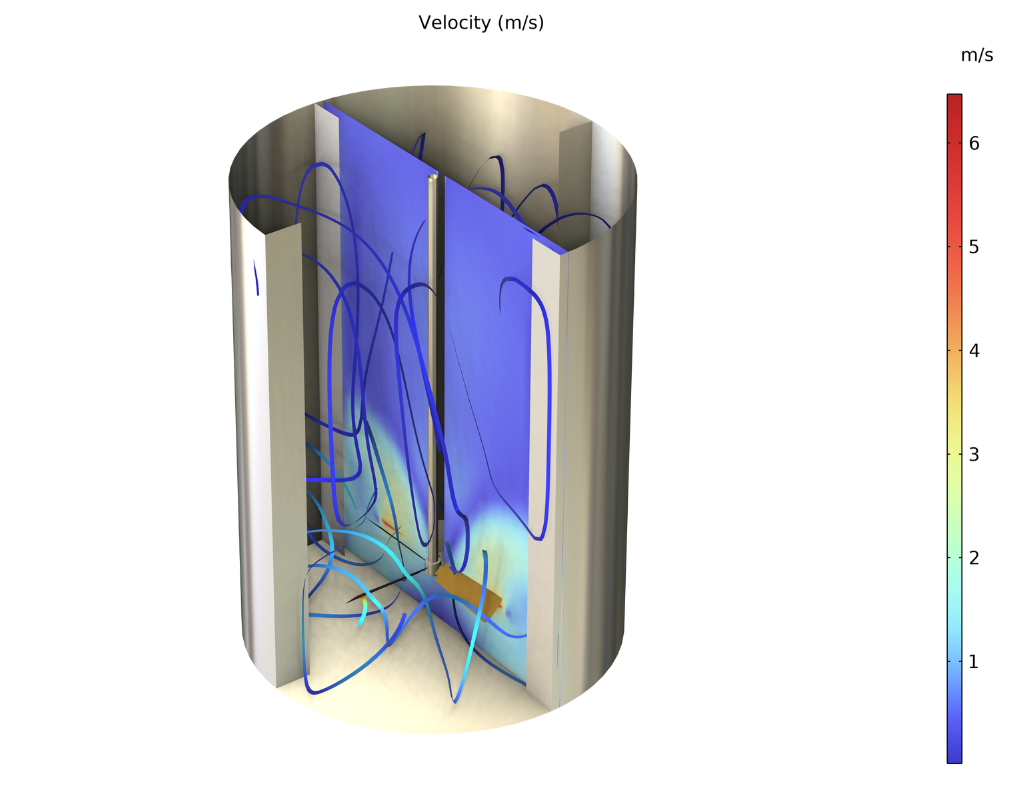

The Modular Mixer tutorial model provides thorough instructions on how to model three mixing process scenarios:

- A laminar mixing problem in a flat-bottom mixer with a Rushton turbine

- A turbulent mixing problem in a dished-bottom mixer with a pitched blade impeller using the k-epsilon (k-ε) turbulence model

- A turbulent mixing problem in a dished-bottom mixer with a pitched blade impeller using the k-omega (k-ω) turbulence model

Using this tutorial model, one can easily modify the mixer geometries to better fit their specific mixer application and modeling needs. Get an in-depth look at this model and download the related MPH file in the Application Gallery.

The model geometry for a baffled flat-bottom mixer with a Rushton turbine (left) and a baffled dished-bottom mixer with a pitched four-blade impeller (right).

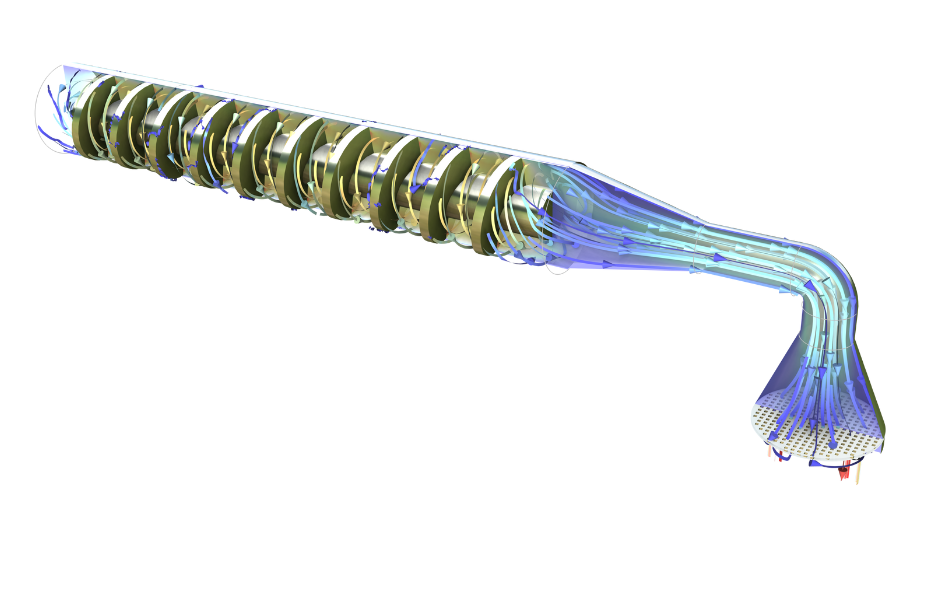

Pasta Extrusion

Pasta extruders are often found in industrial pasta factories, as they provide an efficient, simple, and fast way to produce pasta of varying shapes and sizes. These machines are able to shape a combination of semolina (a type of flour) and water into different raw pasta forms (like spaghetti) through their many components. A particular component of importance is the extrusion screw, which, upon its motion, converts the semolina and water into a dough and pushes it through the machine’s extruding bell, which consists of a screen with many millimeter-sized holes. The dough exits the machine as strands of pasta through two different outlets. In the rightmost image below, you can see a model representation of such a pasta extruder.

At left: Dry pasta of varying shapes and sizes. Photo by Karolina Kołodziejczak on Unsplash. At right: Flow field and geometry of a pasta extruder, including the extrusion screw, bell, millimeter-sized holes, and two outlets.

Although pasta extruders have been around for a long time, the efficiency of these machines isn’t perfect. Issues that can occur with the extruder design include:

- Incomplete mixing of flour and water

- Uneven pressure distribution and extrusion velocity

- Poor circulation of dough

Using the Pasta Extrusion tutorial model, you can predict how conditions inside the extruder may cause such problems for different dough recipes. Learn more about this model and see how to set it up here.

Household Appliance

Microwave Oven

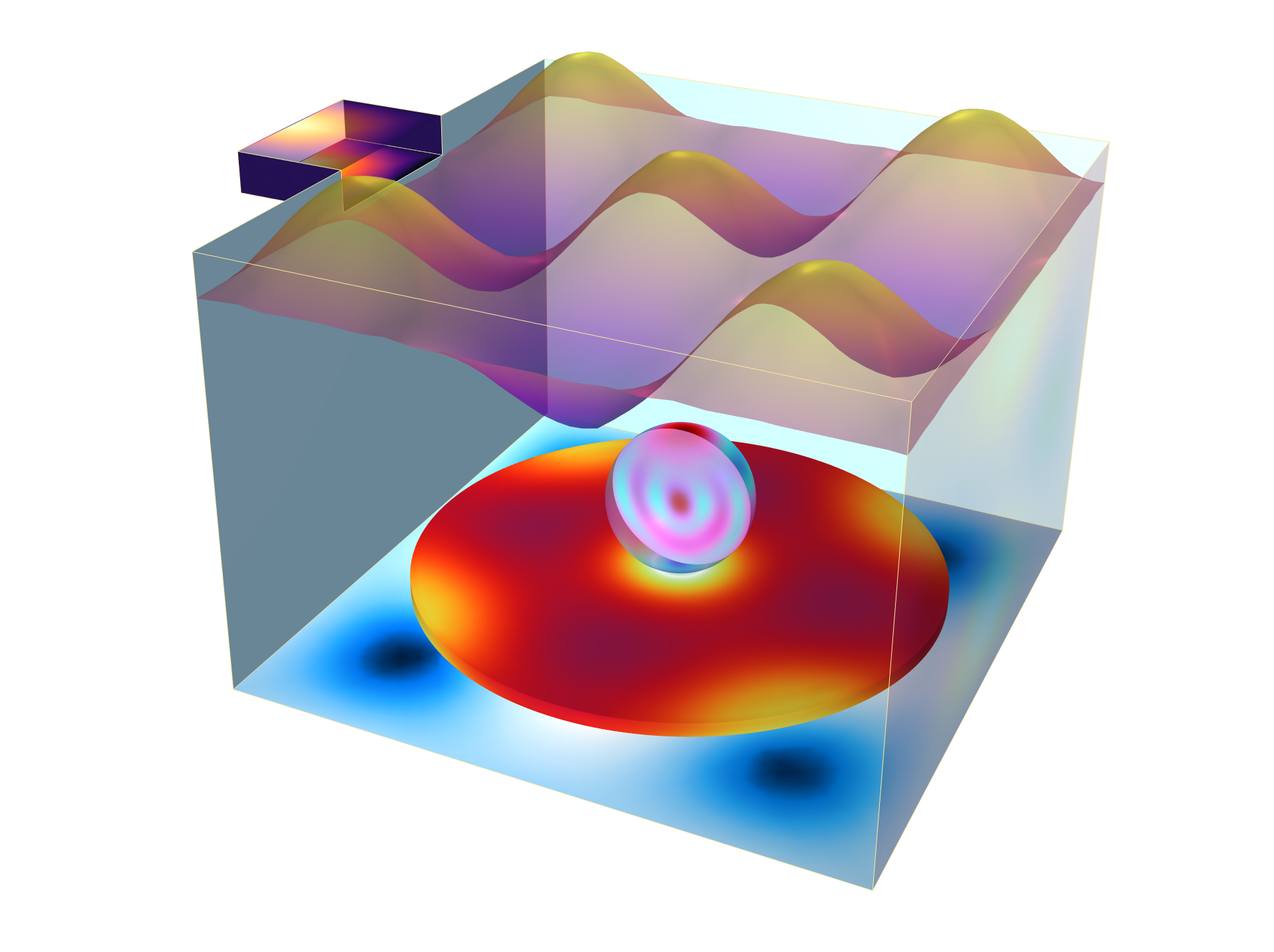

Many years after Percy Spencer’s discovery of the microwave oven, its design is still being researched and enhanced. One reason for this is because the technology that enables this common household appliance to cook a meal in a matter of minutes isn’t without its flaws. A common frustration among many microwave owners is the appliance’s inability to always evenly heat food. When a microwave unevenly heats a meal, the consumer is left with a partially frozen, partially cooked breakfast, lunch, dinner, or snack. Certain meals are unevenly cooked in a microwave because its ingredients consist of varying water content; the more water content a food has, the faster it will heat. Another reason for meals being unevenly microwaved is due to the complex oscillating patterns that occur in the appliance when it’s in use.

RF modeling can be used to better understand the physics at play in a working microwave. For example, the Microwave Oven tutorial model can be used to model the heating process in a microwave while it cooks a potato. In this example, the microwave is modeled as a copper box connected to a 2.45 GHz microwave source. A rectangular waveguide in the model directs the microwaves toward the oven’s center. Explore the model in depth here.

The Microwave Oven model.

Further Reading

Want to learn more about the use of simulation in the food industry? Browse the stories below to see how COMSOL Multiphysics was used to study the interconnected physics involved in the production of puffed snacks, an award-winning recipe for a fried halibut fish roll, and a world-famous candy bar.

- Engineering Perfect Puffed Snacks

- COMSOL Assists Master Chef in Winning International Competition

- The Sweet Side of Simulation Behind the Scenes at Nestlé

Reference

- “Wheaties®,” Wikipedia, Wikimedia Foundation, 8 September 2022; https://en.wikipedia.org/wiki/Wheaties

Wheaties is a registered trademark of General Mills IP Holdings II, LLC.

Comments (1)

Maral Madera

November 16, 2022Thanks for sharing this article here. I wasn’t sure about it. But I am glad to read this article here.