Dynamic Wall Heat Exchanger

Application ID: 47371

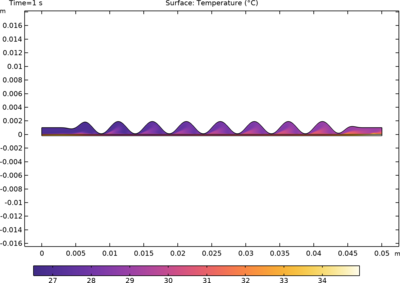

The heat exchanger in this tutorial model contains a dynamic wall with an oscillating wave shape. The deformation induces mixing in the fluid and reduces the formation of thermal boundary layers. Hence, it increases heat transfer between the walls and the fluid. In addition, the wave shaped deformation induces a pumping effect similar to the peristaltic pumping that compensates the pressure losses. This model combines the Conjugate Heat Transfer multiphysics coupling for the heat transfer in the solid and the fluid with the Moving Mesh interface to handle the wall and channel deformation. A first stationary study models the static configuration and the second time-dependent study computes the dynamic behavior.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® and

- either the Battery Design Module, CFD Module, Chemical Reaction Engineering Module, Corrosion Module, Electrochemistry Module, Electrodeposition Module, Fuel Cell & Electrolyzer Module, Heat Transfer Module, Microfluidics Module, Plasma Module, Polymer Flow Module, Porous Media Flow Module, or Subsurface Flow Module

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.