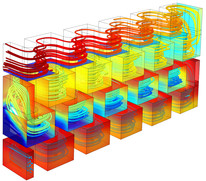

Fine Chemical Production in a Plate Reactor

Application ID: 8589

Plate reactors running under continuous conditions have emerged as candidates to replace batch reactors, primarily in fine chemicals and pharmaceuticals production.

One of the advantages of the plate reactor design is that it allows for efficient temperature control of the reacting fluid. For instance, this means that the heat released from strongly exothermic reactions can be readily dissipated and more concentrated reaction mixtures can be run through the system. Plate reactors show promise to provide more energy-efficient production in a smaller package.

This model demonstrates how to set up and solve the coupled flow, mass, and energy transport equations describing the reacting flow in a plate reactor.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® and

- either the Battery Design Module, Chemical Reaction Engineering Module, Corrosion Module, Electric Discharge Module, Electrochemistry Module, Electrodeposition Module, or Fuel Cell & Electrolyzer Module and

- either the Battery Design Module, CFD Module, Chemical Reaction Engineering Module, Corrosion Module, Electrochemistry Module, Electrodeposition Module, Fuel Cell & Electrolyzer Module, Microfluidics Module, Polymer Flow Module, Porous Media Flow Module, or Subsurface Flow Module

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.