Charging of a Metal Hydride Tank

Application ID: 129981

Metal hydride tanks offer safe hydrogen storage, thanks to their low reactivity, and a relatively high hydrogen density. When developing metal hydride hydrogen tank designs, modeling and simulation is useful for optimizing operating conditions, such as gas composition, pressure, and temperature, based on specific design parameters like metal composition, porosity, and geometric dimensions.

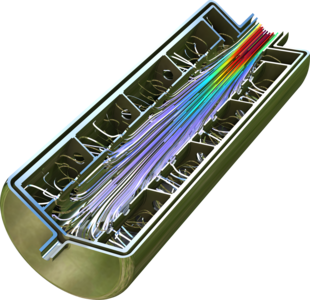

In this example, the model represents the recharge process of a hydrogen tank equipped with a metal hydride foam. It includes the adsorption kinetics and thermodynamics and computes the flow, concentrations, and temperature fields.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® and

- either the Battery Design Module, CFD Module, Chemical Reaction Engineering Module, or Fuel Cell & Electrolyzer Module and

- either the Battery Design Module, Chemical Reaction Engineering Module, Corrosion Module, Electric Discharge Module, Electrochemistry Module, Electrodeposition Module, or Fuel Cell & Electrolyzer Module

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.